3D Design (CAD)

Precision Engineering Through Digital Modeling

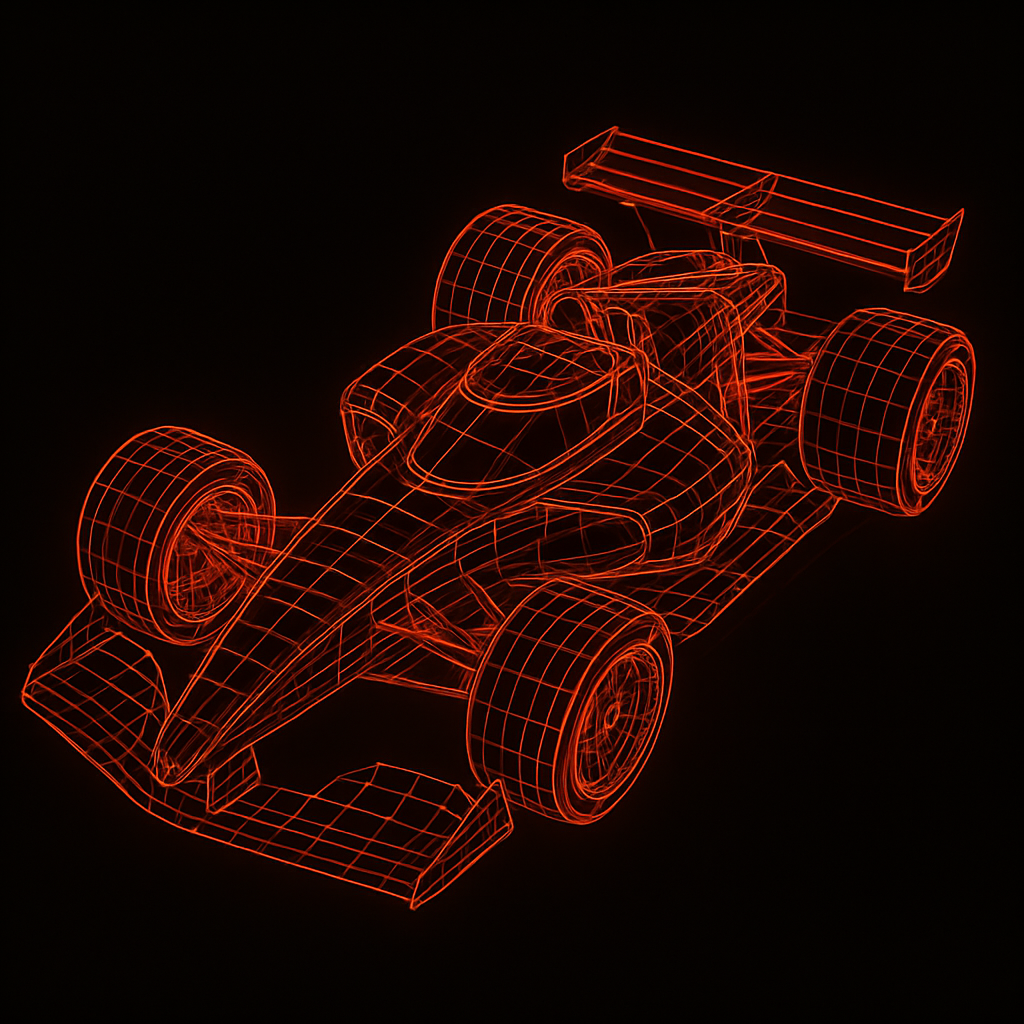

Design Overview

Our CAD workflow combines industry-standard software with innovative design principles to create a competitive F1 in Schools race car. Every component is meticulously modeled for optimal aerodynamics, weight distribution, and structural integrity.

Design Process

Concept Sketching

Initial design concepts and aerodynamic profiles

3D Modeling

Detailed CAD modeling with precise measurements

CFD Analysis

Computational fluid dynamics testing and optimization

Final Refinement

Weight optimization and structural validation

Genetic Algorithm Optimization

Evolutionary Design for Peak Performance

To achieve the perfect front wing profile, we employ Genetic Algorithms (GA) powered by ANSYS Fluent CFD simulation. This computational method mimics natural selection to evolve designs through thousands of iterations. Each generation is rigorously tested in ANSYS's virtual wind tunnel, where flow visualization and aerodynamic analysis guide the evolution toward optimal solutions that human intuition might miss.

1. Initial Population

Generate a diverse set of random wing profiles with varying angles and curvatures.

2. Fitness Evaluation (ANSYS CFD)

Each design is tested in ANSYS Fluent's virtual wind tunnel to measure downforce, drag coefficient, and flow characteristics.

3. Selection & Crossover

The best-performing designs are 'bred' together, combining their successful aerodynamic traits.

4. Mutation & Evolution

Small random changes are introduced to maintain diversity and discover new aerodynamic possibilities.

Technical Specifications

Software & Tools

Fusion 360

Primary CAD modeling and assembly

- Parametric design

- Cloud collaboration

- Simulation tools

SolidWorks

Advanced structural analysis

- FEA analysis

- Motion studies

- Rendering

ANSYS Fluent

Aerodynamic simulation

- CFD analysis

- Flow visualization

- Drag optimization